Welcome To Native Power Technology Co., Ltd.

Native Power Technology Company Limited is playing major role in Myanmar’s Oil and Gas Field and it is leading by Myanmar Nationals who has abundant well -Experienced Electrical, Mechanical, and Geologist Expert from Ex. MOGE. NPT has been dedicated in supplying the highest quality oilfield products, downstream equipments & engineering service in Filtration, Metering,

Pressure Reducing and LPG Storage, Distribution Terminal, Cathodic Protection, Electrical Power System Installation, Commissioning Service and solution provider in Myanmar. Our engineers have received continuous professional courses in our field and well applied these requirements. Therefore, we have achieved strongly recommended and unparalleled track record from Myanma Oil and Gas Enterprise. We are willing to provide you the first rate service with our advanced technology and high-qualified staff. NPT sincerely invites friends from all over the world to cooperate with us and create a bright future together.

EVENT HISTORY

PROJECT INSTALLATION OF 6” 1.5 MILES NATURAL GAS PIPE LINE CONSTRUCTION AND 3 MMSCFD GAS FILTRATION, REDUCTION AND METERING GAS SKID INSTALLATION AT KANBAUK (PETRO & TRANS)

PROJECT INSTALLTION OF 10” 1 MILES NATURAL GAS PIPE LINE CONSTRUCTION AT THAKETA, YANGON (VPOWER)

PROJECT INSTALLATION OF 6” 866 METER TEMPORARY GAS PIPE LINE CONSTRUCTION AT KYAUK PHYU (VPOWER)

PROJECT INSTALLATION OF 40 MMSCFD FILTRATION, REDUCTION AND METERING SKID SUPPLY & INSTALLATION (MAXPOWER THAKETA)

CATHODIC PROTECTION SYSTEM INSTALLTION OF YENANCHAUNG-MAGWAY 20” (18 MILES) GAS PIPE LINE

PROJECT INSTALLATION FOR COOLING WATER PIPE LINE (SUPPLY & RETURN PIPE LINE)(KYAW SWAR FERTILIZER)

PROJECT INSTALLATION FOR 8” (1 MILES) NATURAL GAS PIPE LINE INSTALLATION, MAIN GAS SKID INSTALLATION OF GAS-FIRED COMBINED CYCLE POWER STATION (KYAUK PHYU)

Cathodic Protection System Installation for Naungdon - Ywama 14 inches Gas Pipe Line (32) Miles.

Project Installation for 10" Natural Gas Piping System, 145 MW Gas Engine Power Plant at Bellin (Powergen Kyaukse) (2018-2019)

14" Pipe Sleeve buried for Road Crossing at Bellin (Powergen Kyaukse) (2018-2019)

Welding Processing for 4" HRC Line at Bellin (Powergen Kyaukse) (2018-2019)

FAT (Factory Acceptance Test) for Internal Gas Skid and GRMS Skid at TechSep Engineering (India)

Internal Gas Skid Mobilization

Installation Service for Internal Gas Skid at Bellin

Internal Gas Skid with 8 Gas Train System for Gas Engine at Bellin (Powergen Kyaukse Power Plant) (2018-2019)

Main Gas Skid Assemble and Installation at Bellin (Powergen Kyaukse Power Plant) (2018-2019)

On going Project of Process Pipe Line Construction at DENKO (Thilawa) (2019)

NPT Tool Box Talk Meeting at DENKO Site

CATHODIC PROTECTION SYSTEM INSTALLATION FOR 30” DOMESTIC NATURAL GAS PIPE LINE

| Location | : Ywama-Hlawga-Tharketa in Yangon |

| Project | : CATHODIC PROTECTION SYSTEM INSTALLATION |

| Project type | : Tunkey {Engineering, Procurement, Commissioning (EPC)} |

| Purchaser |

: Myanma Oil and Gas Enterprise |

| Contract | : 09-12-2013 |

| Commissioning | : 30-05-2015 |

| Pipe size | : 30 inches |

| Length | : 35 Miles |

| Material | : CATHODIC PROTECTION EQUIPMENT and Accessories |

| Progress |

: Native Power Technology supplied all man power , materials and technology. |

10 inch x 2 miles Pipe line installation for MEPE

| Project | :Kanbauk 200 MW Combined Cycle Power Plant |

| Project type Purchaser | :Turnkey (Supply materials, Installation and Commissioning) (a)10” x 2 miles Pipe line & installation. (b)Non Destructive Testing (NDT) (c)Cathodic Protection System (d)Gas Filtration Skid, Pressure Reducing Skid and Fiscal Metering |

| Location |

: Kanbauk,Yephyu Township,Taninthayi Region, Myanmar |

| Purchaser | : Andaman Power and Utility Co. Ltd. |

| Contract | : 09-12-2014 |

| Commissioning | : 01-04-2015 (Pipeline ,NDT , Cathodic Protection) |

| Gas Volume | : 50MMSCFD |

| Pipe size | : 10 inches |

| Length | : 2 Miles |

| Pressure | :400PSI |

10” x 2 miles Natural Gas Pipe line installation 10” x 2 miles Natural Gas Pipe line installation Project for MEPE at kanbauk |

10” x 2 miles Pipe line Route |

10” x 2 miles Pipe line installation 10” x 2 miles Pipe line installation Project for MEPE |

Pipe Transportation Pipe Transportation |

Pipe Transportation Pipe Transportation |

Laying pipeline Laying pipeline |

Laying pipeline |

Pipe line Dozing |

10” x 2 miles Pipe line |

10” x 2 miles Pipe line |

Pipe line Dozing |

Pipe laying under vehicle road |

Pipe laying on the concrete block Pipe laying on the concrete block |

Pipe line warning sign for safety Pipe line warning sign for safety |

5G welding Job 5G welding Job |

5G welding Job |

Heat shrinkable Sleeve |

Testing of pipe |

Pressure Test (Hydrotest) |

Foam Pig launching |

Pressure Test (Hydrotest) |

Natural Gas pipe line flushing |

10” x 2 miles Pipe line |

Compensate communities |

|

Laying Titanium Mixed Metal Oxide Anode and |

|

Laying TI-MMO Anode and installation of |

10” x 2 miles Pipe line back filling |

For External Gas Pipe Line of 60T/D Newsprint Paper Mill Project (Thabaung)

| Location | : 60Tonage per day Newsprint Paper Mill, Tharbaung Township, Ayeyarwaddy Region |

| Project | : External Gas Pipe Line of 60T/D Newsprint Paper Mill Project |

| Project type | : Turnkey {Engineering, Procurement, Commissioning (EPC)} |

| Purchaser | : PAPER & HOME UTILITY INDUSTRIES ,Ministry of Industry |

| Contract | : 09-12-2013 |

| Commissioning | : 30-05-2015 |

| Pipe size | : 6 inches |

| Length | : 2 Miles |

| Material | : Pipe, Coalescing Gas Filter skid, Pressure Reduction Skid ,Metering System and Accessories |

| Progress | : On 2014 – 2015: We Native Power Technology Co.,Ltd. as “ Contractor” had been contracted with PAPER & HOME UTILITY INDUSTRIES (PHUI), an enterprise organized and existing under the law of the Republic of the Union if Myanmar as “Purchaser” for Gas Regulating & Metering Station and 6” Pipe Line Installation Services. The “Purchaser” has being of Myanmar wishes to construct, maintain, own and operate Gas Coalescing Filter Skid, Metering System and Pressure Reduction Skid for External Gas Pipe Line for 60 T/D Newsprint Paper Mill Project (Tharbaung). 60T/D Newsprint Paper Mill Project (Tharbaung) The “Contractor” shall obtain the “Purchaser” approval for any deviations from the requirements of the specification, and/or codes, standards and specifications referred to in this Contract. And following the scope of work to be performed by Contractor ; Coalescing Gas Filter Skid Pressure Reduction SkidF low Measurement System - All Piping Network - All skid cable laying and instrumentation - Factory Acceptance Test (FAT), Site Acceptance Test (SAT) - Pre – commissioning, Commissioning & Start – up. |

External Gas Pipe Line 60Ton per Day |

6” Pipe Line 1300ft |

6” Pipe Line 1300ft Installation 6” Pipe Line 1300ft Installation and NDT Test, Hydro Test |

6” Pipe Line 1300ft Installation |

6” Pipe Line 1300ft Installation |

6” Pipe Line 1300ft Installation |

|

Mawlamyaing 230MW MEPE Gas Turbine Project

| Location | : Mawlamyaing Ngantae Gas Turbine |

| Purchaser | : Myanmar lighting (IPP) Co., Ltd. |

| Contract | : 09-12-2013 |

| Commissioning | : 24-03-2015 |

| Gas Volume | : 50MMSCFD |

| Pipe size | : 14 inches |

| Length | : 2 Miles |

| Pressure | : 350PSI |

| Project type | :Turnkey (Supply materials, Installation and Commissioning) |

Mawlamyaing 230MW |

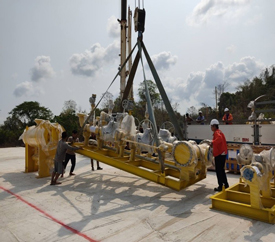

Installation of Gas Filter Skid |

Installation of Gas Filter Skid |

Mawlamyaing 230MW Mawlamyaing 230MWMEPE Gas Turbine |

FL Smidth Products and Services seminar

| FL Smidth A/S & Native Power Technology Co., Ltd. Presented as the following title at Mandalay hill resort hotel on 19-05-2015 | |

|

Mr. Mikkel Diness Vinedeloev |

Greeting message |

|

Mr. Rune Hurttia |

The FL Smidth Cement Plant- Reliability and Effiency Delivered |

|

Mr. Jacob Joergensen |

FL Smidth Customer Services |

|

Mr. Leo Carnevale |

Innovative , Solutions for your Packing Plant |

|

Mr. Ning Shen Tan |

Dosing System |

|

Mr. Sujith Varghese George |

Reliable Gear Technology comes from Progress |

|

Mr. Rasmus Ellefsen |

Air Pollution Control for the cement industry |

|

|

|

|

| FL Smidth Products and Services seminar | |

Aviation Turbine Fuel 16" Ø Pipe Line Project

| Location | : International Airport in Yangon |

| Project | : Aviation Turbine Fuel 16" Ø Pipe Line Project |

| Project type | :Turnkey {Engineering, Procurement, Commissioning (EPC)} |

| Purchaser | : Myanma Petroleum and Product Enterprise complex 44, Nay Pyi Taw, Myanmar |

| Contract | : 08-12-2011 |

| Commissioning | : 30-09-2013 |

| Pipe size | : 16 inches |

| Length | : 0.32Miles |

| Material | : Pipe and CATHODIC PROTECTION EQUIPMENT with Accessories |

| Progress |

:Material Collection (Foreign) Site Preparation Dismantling the associated materials in Hydrant Pits Cutting , Breaking and removing of con; slab(Apron) |

Aviation Turbine Fuel |

Aviation Turbine Fuel |

Site preparation (Trenching) |

Site preparation(Old Pipe line) |

Site preparation |

|

Maintenance and Service

|

|

|

|

|

|

Join Us

Our Visitors

Contact Us

![]() No. 149/14, Phan Chat Wun U Shwe Oue Street, Section (1), Ward (113), East Dagon, Industrial Zone, Yangon, Myanmar.

No. 149/14, Phan Chat Wun U Shwe Oue Street, Section (1), Ward (113), East Dagon, Industrial Zone, Yangon, Myanmar.

![]() 95-1-704246

95-1-704246

![]() +95-1-8566187

+95-1-8566187

![]() nativepowercontact@gmail.com, infonative.mm@gmail.com

nativepowercontact@gmail.com, infonative.mm@gmail.com

![]() nativepowertechnology.com

nativepowertechnology.com

Test Points route of Cathodic Protection for

Test Points route of Cathodic Protection for

Test point and Preparation

Test point and Preparation